Vacuum systems

We build special vacuum systems for many purposes.

Vacuum decay leak testing systems with gas filling

Equipment for vacuum decay leak testing and SF6 gas filling

- With Pirani and Piezo vacuum measurement

- With PC/PLC control.

- With Alcatel 2033 SD vacuum pump.

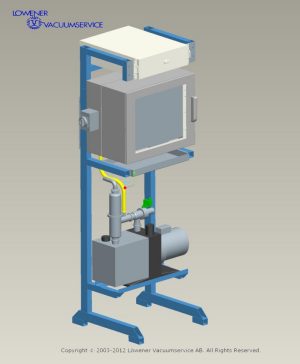

Vacuum pumping and gas filling system

- With Pirani and Piezo vacuum measurement

- With PLC control.

- With Alcatel 2033 SD vacuum pump.

Vacuum decay leak testing with gas filling

- With Pirani and Piezo vacuum measurement

- With PLC control.

- With Alcatel vacuum pump.

Vacuum decay leak testing with gas filling

- With Pirani and Piezo vacuum measurement

- With PLC control.

- With Alcatel vacuum pump.

Vacuum drying systems

Vacuum drier with cylindrical chamber.

- Stainless steel chamber mounted on support

- Pumps mounted inside the cabinet.

- With movable shelve.

- Vacuum system PLC-control.

- Well balanced door for easy opening and shutting.

- Often used for drying metallic components after they have been cleaned in water.

Vacuum drying plant with vertical chamber and heating.

- Stainless steel chamber mounted on support

- Pumps mounted under the chamber.

- With movable shelve.

- Vacuum system PC/PLC-control with CitectScada.

- Heating in wall, lower part and lid.

Vacuum dryer with cylindrical chamber.

- Stainless steel chamber, diameter 900 mm, length 1500 mm, mounted on support

- Pumps mounted inside the cabinet.

- Well balanced door for easy opening and shutting.

- One-stage multi-vane vacuum pump in series with roots pump for high pumping capacity.

- Often used for drying metallic components after they have been cleaned in water.

Vacuum dryer with cylindrical chamber.

- Stainless steel chamber, diameter 350 mm, length 900 mm, mounted on support

- Pumps mounted inside the cabinet.

- Well balanced door for easy opening and shutting.

- One-stage multi-vane vacuum pump.

- Often used for drying metallic components after they have been cleaned in water.

Multichamber vacuum drying system

- The 24 chamber systems work with the same temperature and vacuum level for all chambers.

- Each chamber has its own control of drying time.

- The chambers are ca 1 liter in volume with opening diameter 100 mm.

- Each chamber can be dismounted and the dried material inside can be kept under vacuum until it is needed later on.

- It is usual to work with a lot more than 24 chambers but only 24 can be in the drying system at the same time.

Oil free vacuum drying system with multistage roots vacuum pump

- Fully automatic with capacitance vacuum measurement gauge.

Oil free vacuum drying system with Alcatel dry multiroots pump built into the system.

- Fully automatic with capacitance vacuum measurement gauge.

UHV thin film coating deposition systems, other UHV systems and HV systems

UHV thin film deposition coating system with e-beam-gun, resistance evaporators and effusion cells with cryo pump. The cryopump is a CTI.

- With Mils rotary vane pump and Pedro Gil roots pump and rotary vane pump Alcatel for fast pump down.

- With HPS Digital Pirani-instrument 945 to control pump down.

- With ASM142 as leak find equipment.

High vacuum plant with turbo pumps.

UHV-system, ultra high vacuum

Quadrupole mass spectrometer for multigas leak detection or residual gas analysis.

Quadrupole mass spectrometer for residual gas analysis.

- With SRS quadrupole and Adixen turbo vacuum pump and dry Adixen backing pump.

- Controlled by PC.

- PC and all pumps placed in noise reduction box on wheels.

Multi-gas leak detector with SRS quadrupole mass spectrometer and Adixen turbopump and rotary vane pump.

- Used for multigas leak detection to find out what is leaking into a vacuum system or with a sniffer to locate a leak, working as a SF6 leak detector or a refrigerant leak detector.

- The vacuum pumps are placed in a noise reduction box on wheels.

Quadrupole mass spectrometer SRS with vacuum system with Adixen turbo and rotary vane pump

- Can be used for multigas leak detection or residual gas analysis.

- In a coating plant or vacuum furnace you can know that to check that conditions are right before starting the process. You choose certain amu for doing this like mass 4 for helium leak detection, 16, 17 and 18 to see if there might be a leak in the water-cooling and mass 28 (nitrogen) and 32 (oxygen) will show if you have an air leak. Use other amu to see if valves for process gases are leaking.

- Used as a multi-gas leak detector it can be used to detect gas like R134A in the refrigeration industry.

- Can also be used for SF6 gas leak detection to detect leaking of SF6 in gas isolated switches

Vacuum gauges calibration equipment

Vacuum gauges calibration equipment

- Automatic calibration of gauges.

- For Pirani, Penning, capacitance, piezo and other gauges.

High vacuum calibration plant for calibration of vacuum measurement instruments and gauges

- Manual calibration of gauges.

- For Pirani, Penning, capacitance, piezo and other gauges.

Vacuum calibration system for calibration of vacuum measurement gauges

- Calibration of gauges.

- For Pirani, Penning, capacitance, piezo and other gauges.

Vacuum degassing systems for removal of air and water.

Mobile vacuum degassing plant for removal of air and water in oil.

Mobile vacuum degassing plant for removal of air and water in oil.

Vacuum degassing system. System with GPC Pirani gauge and instrument and Alcatel rotary vane pump Pascal.

Flight height, altitude, simulation systems

Flight height simulation chamber

Can also be used as package leak altitude simulator.

- With capacitance gauge.

Space simulation system

- Also named TV-chamber or thermal vacuum chamber.

Central vacuum systems with buffer volume

Central vacuum system with buffer chamber

- Vacuum pump Evisa 200.

- Buffer tank with two connections.

- Manometer.

- Vacuum measurement Piezo.

- Stainless steel bellow sealed angle valve between pump and buffer chamber.

- Different vacuum levels easily programmed.

- Simple and good price central vacuum staion.

- Click on pictures for bigger pictures.

- Can be delivered with different vacuum pumps.

Compositvac vacuum pumping system for plastic industry with two vacuum levels, one for holding the mold shut and one to pump where resin is injected.

- Used for RTM Light, vacuum molding for composites. Also for mold closing during injection.

- Also for VARI, Vacuum AssistedResin Injection, VM, Vacuum Molding and VARTM, Vacuum Assisted Resin Transfer Molding.