Helium leak detectors.

We build special helium leak detectors and helium leak testing systems. We also sell helium leak detectors.

We produce special helium leak detectors for very fast testing of small products and leak detectors that have very high pumping capacity. Some are made to work under rough industrial conditions. When building a special leak detector we start with a standard leak detector like Adixen ASM340 and add components like vacuum pumps, valves, PLC or PC control and testing chambers.

We always have used helium leak detectors on stock and mostly also new ones and demo-units.

Helium leak detectors

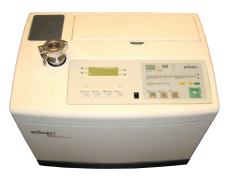

ASM 340 Helium leak detector Multipurpose leak detector ASM 340-series

- Minimum detectable helium leak: <5 x 10 -12 mbarl/s

- Rotary vane pump: Pascal 15 m3/h

Applications:

- Production and quality control of products.

- Outboard testing of pressurized parts (sniffing test).

- Sealed instruments and devices.

- Vacuum furnaces.

- Refrigeration systems and components.

- Vessels and tanks.

- Gas handling systems and components.

- Electronic devices.

ASM 340 D Helium leak detector - Dry

- Minimum detectable helium leak: <5 x 10 -12 mbarl/s

- Pump: 3.4 m3/h

Applications:

- Production and quality control of products.

- Outboard testing of pressurized parts (sniffing test).

- Sealed instruments and devices.

- Vacuum furnaces.

- Refrigeration systems and components.

- Vessels and tanks.

- Gas handling systems and components.

- Electronic devices.

Helium Leak Detection Workstation ASM 1002

- To leak test small components in production.

- Leak testing hermetically sealed IC packages, electronic components, relays.

- Leak test gauges, sensors.

- Leak test hermetically sealed IC packages, electronic components, relays.

- Leak test small valves and fittings.

- Leak test medical devices.

- Leak testing feed-throughs, switches, connectors.

- Sample leak testing of food or pharmaceutical packages.

Portable dry sniffer helium leak detector ASM102S

Applications:

- Control and maintenance of any part or installation used under pressure (outboard testing):

- leak testing underground cables and tubes

- leak testing valves and manifolds

- leak test underground or external storage tanks

- leak test reactors, heat exchangers, vapor generators

- leak test maintenance for air conditioning systems

- leak testing Kerosene tanks (wings and fuselage) after assembly

- maintenance of airplanes: helium leak test wings and fuselage

- off shore helium leak test of gas installations

- leak testing of gas line installations in Semi conductor fabs and aeronautic and aerospace applications

Special helium leak detectors

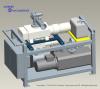

Helium leak detector workstation for small objects

- Helium leak detector for small objects. The objects to be tested may have been sealed in a helium atmosphere or may have been in a high helium pressure chamber for some time. The unit finds very small leaks in a very short cycle time.

Mobile helium leak detector with automatic high pumping capacity

- Helium leak detector with mobile automatic pumping systems with rotary vane pumps and roots pump for fast pump down. With helium leak detector ASM 142, particle filter and Digital Pirani-instrument.

Helium leak detector with high pumping capacity, PDF-file 0.2 Mb

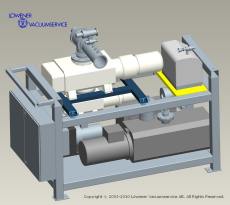

Mobile helium leak detector with automatic very high pumping capacity

- Helium leak detector with mobile big pumping system with rotary vane pumps and roots pump for very fast pump down. With helium leak detector ASM 142, particle filter and Digital Pirani-instrument.

- Used for finding leaks in big test objects like aluminum castings where helium is sprayed from the outside. Gives a short response time from spraying to response on the leak detector. That makes this a practical method to rapidly find leaks in big objects.

Helium leak detector with very high pumping capacity, PDF-file 0.2 Mb

Helium leak detector with automatic very high pumping capacity

- Helium leak detector with big pumping system very fast pump down. With helium leak detector ASM 142, particle filter and Digital Pirani-instrument. Rough pumping with E600 (635 m3/h). High vacuum pumping system with two-stage rotary vane 2063SD and two roots vacuum pumps (500 and 2880 m3/h).

- Used for vacuum pumping and finding leaks in big objects.

Helium leak detector with PC-control and high pumping capacity

- Helium leak detector ASM 142 with PC-control on wheels.

- Two-stage rotary vane Adixen 2033SD and roots in series.

- Gas filling as option.

Helium leak detector with automatic high capacity pumping system with big rotary vane pump for fast pump down. Often used for leak detection on castings.

- The test object is placed on the stainless steel surface. Press start on the control panel and the object will be pumped to the chosen vacuum level and the valve to the leak detector will be opened. Spray helium on the test object (leak location) or put a plastic bag or a container over the object and fill that with helium.

- System size: Width: 1800 mm, Depth: ca 950 mm, Height: 1595 mm.

- Control system: PLC

- Pirani-instrument

Helium leak detector with automatic high capacity pumping system with rotary vane pumps and roots pump for fast pump down. Control system with Pirani-instrument.

- The test object is placed on the stainless steel surface. Press start on the control panel and the object will be pumped to the chosen vacuum level and the valve to the leak detector will be opened. Spray helium on the test object (leak location) or put a plastic bag or a container over the object and fill that with helium.

Helium leak testing equipment

Helium sniffer-probe A63101-L for Alcatel helium leak detector

- 3 m long.

- With connection for Alcatel helium leak detector.

- Protective filter.

Helium sniffer-probe A63105-L

- 3 m long

- With 25KF-Flange.

- Protective filter.

- For many brands of helium leak detectors

Helium leak detector particle inlet filter

- 40KF-flanges, the left one to be mounted on the leak detector

- Inside is a ca 20 µm or a ca 40 µm Filter of sintered bronze.

- Article number with ca 20 µm: A64111

- Article number with ca 40 µm: A64153

Helium leak detector inlet filter exchange-piece

- Article number with ca 20 µm: A64112

- Article number with ca 40 µm: A64113

| Number | Name | Size | Price EURO |

|---|---|---|---|

| U25001 | Particle filter 25/40/25KF | ca 40 µm | 145 |

| A64114 | exchange-piece | ca 40 µm | 49 |

Consisting of two reductions stainless Steel 25/40KF, one filter element sintered bronze inside a 40KF center ring and one clamp 40KF.

Helium leak detector inlet filter

- Two reductions 100ISO-25KF.

- One 20 µm Filter on a 100ISO Centering ring

Chambers for using with leak detector.

- Chambers for using with leak detector. Pumping and measurement flanges. Venting valve, movable working table and sightglass.

- Different sizes. More info: vacuum chambers

- Vacuum pumps and HMI-software as option.

Chambers for mounting on leak detector

- Chambers for mounting on leak detector. Venting valve and lid with handle. Different sizes. More info: vacuum chambers

- If the object is small and already filled with helium a ASM142 with a vacuum chamber is in itself a complete system. You put the object in the chamber and replace the lid. Press cycle on the leak detector it will pump down the chamber, do the testing and tell you if the object leaks more than you have put as max limit.

Chambers for placing on table and using with leak detector.

- Chambers for placing on table and using with leak detector.

- Venting valve and lid with handle.

- Different sizes. More info: vacuum chambers

The product to be helium leak tested may be a heat exchanger, a gas tube, a water-heater, a container, a water valve, a petrol tank, a barrel, a heat pump, a fuel tank, a high voltage switch, a battery, a package, an AC-Component, an air-conditioning component, an electronic component, an oil cooler, a radiator, a fire extinguisher, a plastic container, a plastic drum, an automotive component, a medical device, an electrical device, a refrigeration equipment, a can end, a package, a microchip or something else.

Other methods are vacuum decay systems, pressure decay systems or leak down test, bubble test or air under water leak test and fluorescent dye impregnation. There are also refrigerant ac, ultrasonic and hydrogen leak detectors.